▼The following discussion in Leng Yun fashion community is a discussion and summary of industry issues. These shares are the crystallisation of collective wisdom. (They do not represent the personal views of Leng Yun). It is hoped that this method will benefit more industry professionals!

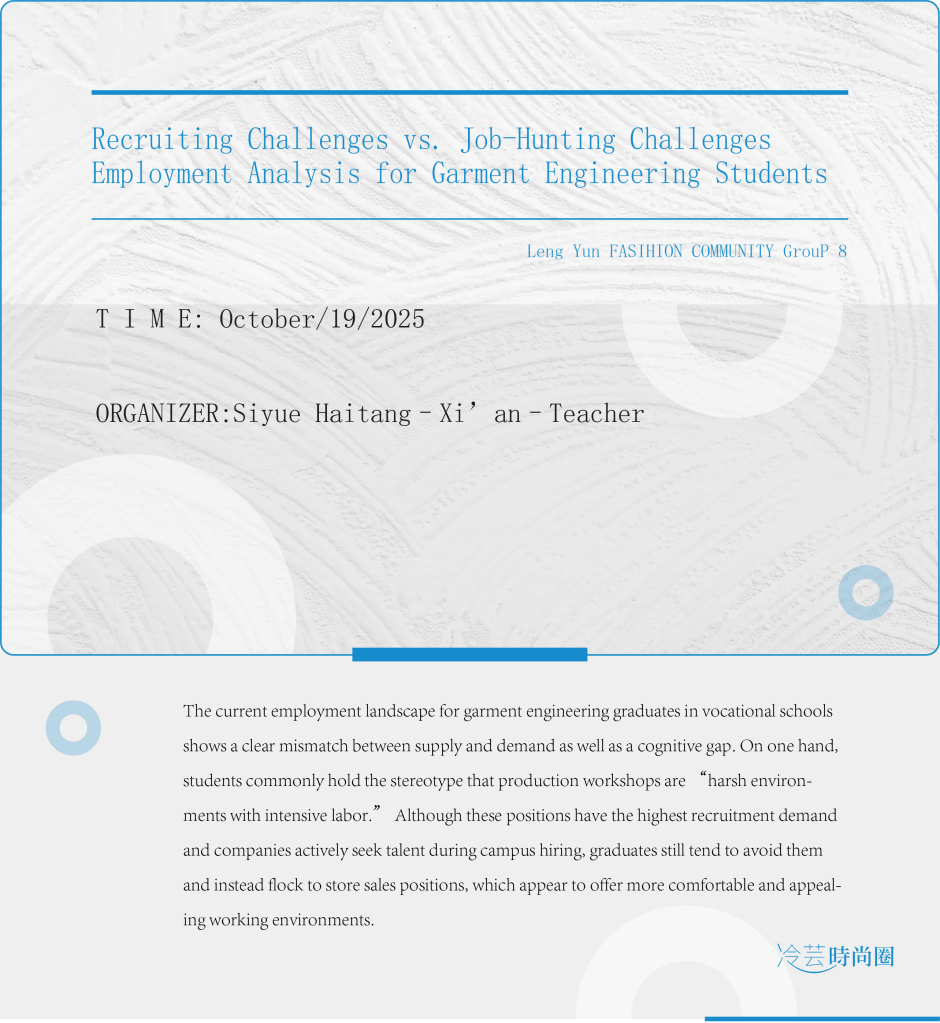

1. The Stark Contrast in Campus Recruitment

As a teacher at a vocational college, every year during campus recruitment I encounter the same frustrating phenomenon:positions in production management—despite extremely high demand from companies—receive little interest from students, while store-level sales positions that appear less demanding attract overwhelming competition.

Behind this phenomenon lies not only students’ job preferences, but also deeper structural problems within the vocational education system.From the enterprise perspective, the demand for production-management talent is indeed very high, covering roles such as supply-chain management and quality control.

However, factories are struggling to attract young employees; production-management positions are dominated by older workers, with little new blood entering the field.

This is not a regional issue but a widespread national problem.In the Yangtze River Delta region, fresh graduates from vocational colleges typically earn around 4,000–5,000 RMB per month, with slightly higher salaries in developed areas such as Shanghai.Most graduates work in sales, production management, or pattern-making.

For well-known institutions such as Donghua University or Beijing Institute of Fashion Technology, bachelor’s graduates in fashion design generally earn 6,000–8,000 RMB, and some master’s graduates can start at 8,000–10,000 RMB.

2. The Real Reasons Students Reject Production Roles

The main reasons vocational college students dislike production-management roles are:

poor perceived working conditions, fear or resistance toward frontline work, and unclear career-development pathways.

Many students expect a “high-end” working environment.Sales positions in shopping malls appear more glamorous and “white-collar,” while entering a workshop feels like becoming “blue-collar.”This identity gap makes it difficult for them to accept production-related jobs.

The deeper issue is cognitive limitation.Many students’ parents have worked in older-style factories and have not passed down a positive impression of industrial workplaces.

These generational stereotypes are difficult to change.

But what is the reality?In fact, top-tier factories today offer work environments comparable to modern office buildings.

For example, during a recent visit by LengYun to Esquel Group, we observed that their Guilin factory’s office environment is very modern.The cafeteria employs professional nutritionists, and meals can be pre-ordered via an app to reduce waste.The company regularly organizes health-focused competitions.Assembly-line workers earn an average of 4,000–6,000 RMB—considered high income in Guilin.The company also partners with the Open University of China, helping over 2,000 employees upgrade their education levels from middle school to junior college or above in the past decade.Such working conditions and development opportunities are by no means inferior to so-called “white-collar jobs.”But both students and teachers lack real understanding of modern factories—their perceptions remain stuck in the past.

3. Geographic Concerns and Career-Growth Ambiguities

Beyond misconceptions about the work environment, job location is another major concern.Many companies are based in Guangzhou and the Yangtze River Delta, yet many students refuse to leave Shanghai or Beijing.This fixation on first-tier cities further limits their job options.

Uncertainty around career development also fuels hesitation.For a fresh graduate entering production management, how do the starting salary, promotion pace, and long-term ceiling compare with sales?Is it possible that production roles are harder at first but offer better long-term opportunities?

In reality, these questions vary by individual rather than by job type.Capable people excel anywhere; lazy people blame circumstances everywhere.But without clear answers, students naturally choose positions that appear more glamorous.Ultimately, these reactions stem from cognitive blind spots.

1. Faculty Quality Is the Core Issue

The biggest problem in China’s education system is not the students, nor the curriculum—it is the faculty.This is a systemic issue, not a criticism of individual teachers.

First, many people choose teaching not out of passion, but for job stability.

A teacher who does not love teaching cannot inspire students to love learning.

Of course, there are teachers who truly care about education.They reflect on teaching quality, pay attention to employment outcomes, and examine gaps between academia and industry.But many others are severely disconnected from real-world practice.

There are deep structural reasons for this.In foreign fashion schools, only about 20% of faculty are full-time; the other 80% are industry professionals serving as adjuncts.But in China, almost no long-term faculty recruitment comes from industry—most teachers move from one ivory tower to another.With no ongoing professional development and limited exposure to industry, how can teachers stay relevant?Schools require teachers to spend short periods in companies each year, but these visits are too brief to make a difference From the company’s viewpoint, what value can a short-term visiting teacher bring?If it is merely a formality, companies gain little, and the collaboration becomes symbolic rather than substantive.

2. Outdated Curriculum

Current vocational programs include courses such as pattern-making (women’s, men’s, grading), garment-construction techniques (skirts, pants, shirts, suits), production management, flat sketching, and electives such as design fundamentals and dyeing.

The problem is that most of this content dates back 20–30 years.Although some new tools and concepts are introduced, the overall curriculum remains outdated.Most teachers are unaware of modern pedagogical methods or industry-relevant tools.

Companies commonly report that graduates in pattern-making are “not practical.”What schools teach does not match industry needs, so companies must retrain students.But after students acquire skills, they often leave, causing companies to feel their investment was wasted.This cycle makes industry-school cooperation increasingly difficult.

3. Superficial Industry–Education Integration

Though schools claim to promote “industry-education integration,” most efforts remain shallow.Industry visits, short-term internships, and guest instructors exist, but the depth is insufficient.Students’ exposure to companies is often brief and superficial, which does not allow meaningful understanding of roles like production management.

Moreover, universities place strict requirements on external instructors—often demanding academic titles that industry professionals do not have.This leads to the paradox where schools want industry input but simultaneously block industry experts from teaching.

Some regions, such as Zhejiang and Fujian, collaborate well with local enterprises through lectures, internships, and mentorships.But many schools still reject practitioners in the classroom—purely because of outdated beliefs.

1. Teacher Self-Improvement Is the Key

Instead of asking how to better match students with companies, we should ask how teachers can grow within the existing system.The true root problems lie in faculty quality and institutional structure—not in students.

Teachers must broaden their learning channels beyond domestic resources:English-language content, international courses, YouTube, art history, philosophy, design, economics—these are crucial for building vision and thinking.Technical skills can be replaced; fundamental thinking cannot.

Platforms like Coursera provide access to top global courses.Advanced degrees such as part-time doctorates are also possible, especially for disciplines that don’t require laboratory work.Today’s learning resources are abundant—any teacher with passion can grow.

2. The Missing Piece: Professionalism Education

Companies report that students often lack professional qualities:

weak physical stamina, poor stress tolerance, low diligence, limited soft skills, and weak communication.Even basic tasks—self-introductions, interview etiquette, proper attire—are often unfamiliar to students.

Employment-guidance courses exist but are not practical enough.Students, on the other hand, often lack initiative.

Thus, both parties contribute to the problem.Schools should introduce required courses on professional conduct, helping students systematically learn essential workplace skills.

3. Embracing Digital Transformation

Skills such as 3D modeling are in increasing demand, with higher salaries due to the combination of aesthetics, technical ability, and professionalism required.

3D tools reduce sample-making cycles and support cost reduction, efficiency improvement, and marketing visualization.Many e-commerce images are already 3D rendered.

Beyond 3D, all roles are moving toward intelligent workflows.But digital tools are just tools—the key remains human thinking.

Teaching software alone is insufficient; thinking models are more essential.These models can be learned through open courses worldwide.

4. Understanding the True Positioning of Applied Undergraduate Education

Applied bachelor programs should produce graduates who are “stronger in hands-on ability than regular undergraduates,” not “stronger in theory than vocational students.”Currently, many students lack both theory and practical ability.

Faculty remains the core issue—without strong teachers, curriculum reform is meaningless.Professionalism courses and thinking-model courses are indispensable.

For many students who could not enter top universities, vocational colleges must deliver real value.Otherwise, four years may become wasted time.

Within existing constraints, teachers must continue learning, updating perspectives, and delivering value to students.The biggest flaw in the system is that those who understand industry pain points are not required to write academic papers, while those required to write papers often do not understand industry realities.

Collaboration between industry professionals and academic faculty may be a solution.

Ultimately, students’ employment struggles and reluctance to endure hardship stem from the lack of value conveyed through education itself.Teachers who begin reflecting on these issues are already ahead of many peers.Continuous learning, cognitive upgrading, and value transmission—within limited conditions—are the true beginning of change.

PS:Translation is done by AI.

Leave a comment